Lightweight Protection, Superior Cushioning – Your Premium EPE Foam Solution

What is EPE Foam?

EPE Foam (Expanded Polyethylene) is a closed-cell, moisture-resistant foam engineered for premium product protection. As a leading EPE foam manufacturer, we specialize in military-grade cushioning solutions for electronics, luxury goods, furniture, and industrial components shipped to the United States.

EPE Foam Manufacturer

Military-Grade Packaging

Luxury Gift Box Padding

Electronics Cushioning

30% Lighter Yet Stronger Than Traditional Fillers – EPE Foam for Superior Protection

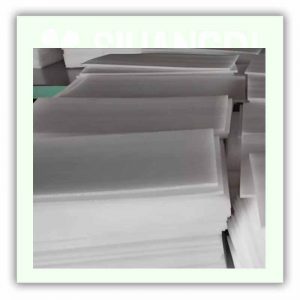

Custom EPE Foam Sheets & Rolls – Precision Cutting for Unique Packaging Designs

Waterproof & Shockproof EPE Foam | Closed-Cell Moisture Barrier | Factory Direct

EPE Foam Product Specifications

Product Name: EPE Foam (Expanded Polyethylene Foam)

Material: Virgin PE (100% Pure Polyethylene)

Color: Snow White (custom colors available)

Width Range: 20-100 cm (adjustable based on requirements)

Thickness Options: 0.5mm / 1mm / 2mm / 3mm / 5mm (standard)

Density: 20-30 kg/m³ (adjustable)

Package Form: Rolls, Sheets, or Custom Die-Cut Pieces

MOQ: 500kg (samples available for testing)

| Parameter | Specification | Test Standard |

|---|---|---|

| Tensile Strength | ≥0.8 MPa | ASTM D3575 |

| Elongation at Break | 100-300% | ASTM D3575 |

| Compression Strength | 30-80 kPa (at 25% deformation) | ASTM D3575 |

| Water Absorption | <0.01 g/cm³ (24h immersion) | ASTM D570 |

| Operating Temperature | -40°C to +80°C | ASTM D696 |

| Flammability Rating | Self-extinguishing (UL94-HB) | UL 94 |

| Thermal Conductivity | 0.035-0.040 W/(m·K) | ASTM C518 |

| Chemical Resistance | Excellent (acids, alkalis, oils) | ASTM D543 |

Professional Customization Process

1. Requirement Submit

✓ Upload CAD/Sample photos

✓ Specify certification requirements

✓ Define packaging application

2. Cross-border Quote

✓ EXW/FOB/DDP terms available

✓ HS Code pre-check (3921.90)

✓ Door-to-door logistics quote

3. Contract Confirmation

✓ Payment: TT/LC/Wise/PayPal

✓ Proforma Invoice provided

✓ Quality standards agreement

4. Production & Shipping

✓ Export packaging (wooden cases)

✓ COO/SGS report included

✓ Real-time shipment tracking

Contact Us for Custom Sizes & Private Label Options

Email:packing@siliangdi.com

Email:SLD@siliangdi.com