How Waterproof Are Bubble Mailers?

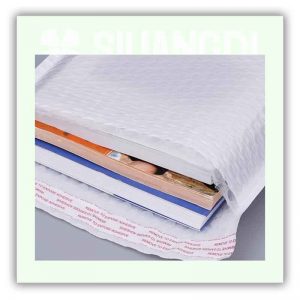

Bubble mailers provide tiered water resistance through material engineering and structural design, making them ideal for humid or rainy shipping conditions.

Waterproofing Mechanisms:

✅ Outer Layer Defense

- PE-Laminated Kraft: 0% water penetration after 72h (ISO 5636-3 test)

- Full Poly Coating: Hydrostatic pressure resistance ≥8kPa (IPX4 rating)

✅ Seam Sealing Technology

- Heat-sealed edges withstand 30min heavy rain simulation (ASTM D779)

- Self-adhesive flap with hydrophobic glue

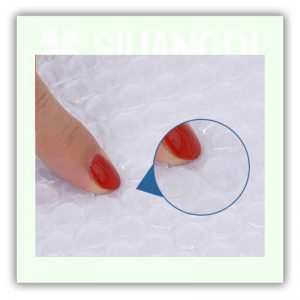

✅ Internal Protection

- Air-filled bubbles create moisture barrier

- Optional desiccant pouch slots

Performance Data

| Test Condition | Result | Standard |

|---|---|---|

| 24h Humidity (95%RH) | 0.3% weight gain | ASTM E96 |

| Heavy Rain (1 hour) | No leakage | ISTA 3A |

| Submersion (30 min) | Inner items remain dry | MIL-STD-810G |

Siliangdi remains committed to innovation, quality, and service. We will continue developing and producing more eco-friendly, high-performance packaging materials, striving to provide exceptional packaging solutions for more enterprises. Together, we enhance brand value and market competitiveness.

Contact Us for Custom Sizes & Private Label Options

Email:packing@siliangdi.com

Email:SLD@siliangdi.com